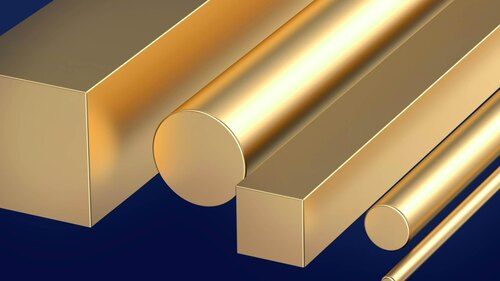

Nickel Aluminum Bronze NES 833

Product Details:

- Temper Hard

- Technique Polished

- Product Type Bronze Fitting

- Material Bronze

- Shape Round

- Color Golden

- Weight 20-50 Grams (g)

- Click to View more

Nickel Aluminum Bronze NES 833 Price And Quantity

- 100.00 INR/Kilograms

- 100 Kilograms

Nickel Aluminum Bronze NES 833 Product Specifications

- 20-50 Grams (g)

- Polished

- Aerospace Decorations Sewage

- Golden

- Bronze

- Hard

- Round

- Bronze Fitting

Nickel Aluminum Bronze NES 833 Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 1000 Kilograms Per Month

- 7 Days

- Yes

- Within a certain price range free samples are available

- Australia North America South America Western Europe Middle East Africa Central America Eastern Europe Asia

- All India

Product Description

NES 833 Part 2

- We specialize in manufacturing & supply of high precision NAB (Nickel Aluminum Bronze) fasteners in any sizes as per your specifications confirming to Naval Engineering Standards (NES).

- The Nickel aluminum bronze material shall be as specified by you, like NES 833 Part 2, BS 2874 Gr, CA104 etc.

- Some of the properties of the Alloy NES 833 Part 2 are detail below

- Nickel Aluminum Bronze NES 833 Part 2

- Nickel Aluminum Bronze NES 833 Part 2 is for good ductility and impact strength. Its distinctive quality is it has a excellent corrosion resistance.

Chemical Composition NES 833 Part 2

|

Element |

% by weight |

|

|

|

Not Less than |

Not More than |

|

Aluminum (see Note 1) |

8.5 |

10.0 |

|

Iron (see Note 2) |

4.0 |

5.0 |

|

Nickel (see Note 2) |

4.5 |

5.5 |

|

Manganese |

|

0.50 |

|

Copper |

Remainder |

|

|

Impurities |

||

|

Zinc |

|

0.40 |

|

Lead |

|

0.05 |

|

Tin |

|

0.10 |

|

Silicon |

|

0.10 |

|

Magnesium |

|

0.05 |

|

Total Impurities |

|

0.50 |

|

NOTE 1 - Aluminum to at least commercially pure 99.7% with maximum magnesium level of 0.05 % is to be used |

||

|

NOTE 2 - Nickel content is to be greater than iron content. |

||

Mechanical Properties

Typical mechanical properties of the alloy are

|

Grade |

NES 833 Part 2 |

|

Tensile Strength (MPa) |

680 |

|

Proof Stress 0.2% (MPa) |

325 |

|

Elongation A5 (%) |

17 |

|

Physical Properties |

|

|

Density |

7.5 gm / cm3 |

|

Electrical Resistivity |

0.172 x 10-6 oms |

|

Thermal Conductivity |

42 W/m.k at 20oC |

NES 833 Part 2 has high corrosion resistance; particularly in marine environments. It also has excellent resistance to cavitations erosion. It largely retains its strength and hardness upto 400o C. It is also resistant to high temperature scaling up to 1000oC.

The dimensional Accuracy & Tolerance of our fastener products are as per the relevant international standards.

Our fasteners are widely used by marine project industries like Ship Building, Pressure Vessels and Heat Exchanger manufacturers, Marine application valve manufacturers and so on.

- Our fasteners are manufactured strictly as per the specified fastener material standard as well as fastener dimensional standard.

- Our fastener products are put through suitable stress relief heat treatment process to get rid of all the undue stresses inculcated during manufacturing process.

- The finished fasteners are thoroughly inspected for the surface defects like Cracks , Seams , Bursts , Folds , Laps , Voids etc .

We are one of the leading manufacturers of high precision NAB (Nickel Aluminum Bronze) fasteners in India.

FAQs of Nickel Aluminum Bronze NES 833:

Q: What is Nickel Aluminum Bronze NES 833?

A: Nickel Aluminum Bronze NES 833 is a type of bronze material that is used in various industries.Q: What is the color of Nickel Aluminum Bronze NES 833?

A: The color of Nickel Aluminum Bronze NES 833 is golden.Q: What is the application of Nickel Aluminum Bronze NES 833?

A: The application of Nickel Aluminum Bronze NES 833 includes aerospace, decorations, and sewage.Q: What is the weight of Nickel Aluminum Bronze NES 833?

A: The weight of Nickel Aluminum Bronze NES 833 ranges from 20-50 grams (g).Q: What is the shape and technique of Nickel Aluminum Bronze NES 833?

A: The shape of Nickel Aluminum Bronze NES 833 is round and the technique used is polished.Q: What is the material used in Nickel Aluminum Bronze NES 833?

A: The material used in Nickel Aluminum Bronze NES 833 is bronze.Q: What is the temper of Nickel Aluminum Bronze NES 833?

A: The temper of Nickel Aluminum Bronze NES 833 is hard.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Aluminum Bronze' category

|

GOVIND METAL CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |