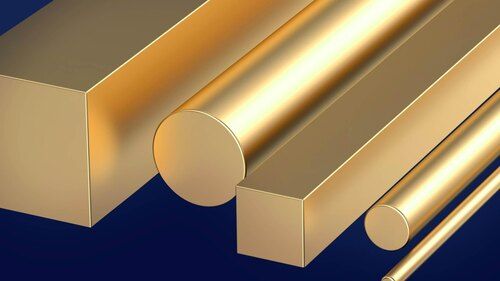

Aluminum Bronze

250.00 INR/Kilograms

Product Details:

- Temper Hard

- Technique Polished

- Product Type Bronze Strip

- Material Bronze

- Shape Rectangular

- Color Silver

- Weight 1-5 Kilograms (kg)

- Click to View more

X

Aluminum Bronze Price And Quantity

- 500 Kilograms

- 250.00 INR/Kilograms

Aluminum Bronze Product Specifications

- Rectangular

- Metallurgy Aerospace Gifts Sewage Filter Decorations

- 1-5 Kilograms (kg)

- Polished

- Silver

- Bronze

- Bronze Strip

- Hard

Aluminum Bronze Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 500 Kilograms Per Month

- 7 Days

- Yes

- Within a certain price range free samples are available

- Australia Western Europe Central America Africa Middle East South America Asia Eastern Europe North America

- All India

Product Description

It was 1989 when we "Govind Metal Co" commenced as Aluminum Bronze manufacturer and exporter, we, being a leading supplier, produce enormous-strength Aluminum Bronze that is an important construction material because of its outstanding properties in terms of colossal mechanical & tensile strength, corrosion & frictional-wear resistivity. Since our coming into being, we have been keeping up the premium standard of quality and excellence and remained an industry leader. Our commitment to the most satisfactory level of customer service, coupled with our expertise in manufacturing the finest grade of Aluminum Bronze in the industry, has been a key to our tremendous growth. We supply and export Aluminum Bronze in various sizes, grades, thickness and dimensions as per the customers application requirements, as well as directly contact with clients to suggest the solution that precisely caters to specific applicational needs.

Employing advanced heat-treatment mechanism for adapting Aluminum Bronze to the extreme corrosive environment, especially marine industry where this alloy finds application in the production of shafts, propellers, gears, as well as characterizing the fine ductility & weldability, favorable coefficient of friction and stiffness. Our category of Aluminum Bronze is excellent choice due to comparatively light in weight, terrific in hardness and is convenient to cast and to use for different application process. Our grade of alloy, offered in varied specifications, is minutely tested on physical and mechanical properties in terms of tensile & yield strength, percentage of elongation and brinell toughness for ensuring optimum results. The alloy is corrosion resistant in nature and lower in wear-rate. Its sharp threads offer greater safety in heavy duty industrial applications.

Key Features:

- Improved machinability

- Oxidation-resistance

- Lower wearing rate

- Withstanding atmospheric degradation

- High-strength

- Anti corrosive

- Greater longevity

- High metal content

- Excellent ductility

- Excellent toughness

- Better operational life

- Excellent wear resistance

- Excellent tensile strength

- Excellent dimensional accuracy

- Corrosion & abrasion resistant

- Ideal for higher temperature

- Well tested before supplied in markets

- Ideal for heavy loads, heavy duty applications

Application Areas:

- Preferably used in engineering industries for different applications areas.

- Preferably used in Marine Sectors for Nuts & Bolts, Propellers, Pump Parts and Ship Propellers

- Preferably used in plumbing as faucets

- Preferably used in liquid media owing to distinct properties

FAQs of Aluminum Bronze:

Q: What is the weight range of Aluminum Bronze?

A: The weight range of Aluminum Bronze is 1-5 Kilograms (kg).Q: What is the temper of Aluminum Bronze?

A: The temper of Aluminum Bronze is Hard.Q: What is the material of Aluminum Bronze?

A: The material of Aluminum Bronze is Bronze.Q: What are the applications of Aluminum Bronze?

A: The applications of Aluminum Bronze are Metallurgy, Aerospace, Gifts, Sewage, Filter, and Decorations.Q: What is the technique and color of Aluminum Bronze?

A: The technique of Aluminum Bronze is Polished and the color is Silver.Q: What is the shape of Aluminum Bronze?

A: The shape of Aluminum Bronze is Rectangular.Q: Is Aluminum Bronze suitable for outdoor use?

A: Yes, Aluminum Bronze is suitable for outdoor use due to its durability and resistance to corrosion.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Aluminum Bronze' category

|

GOVIND METAL CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |